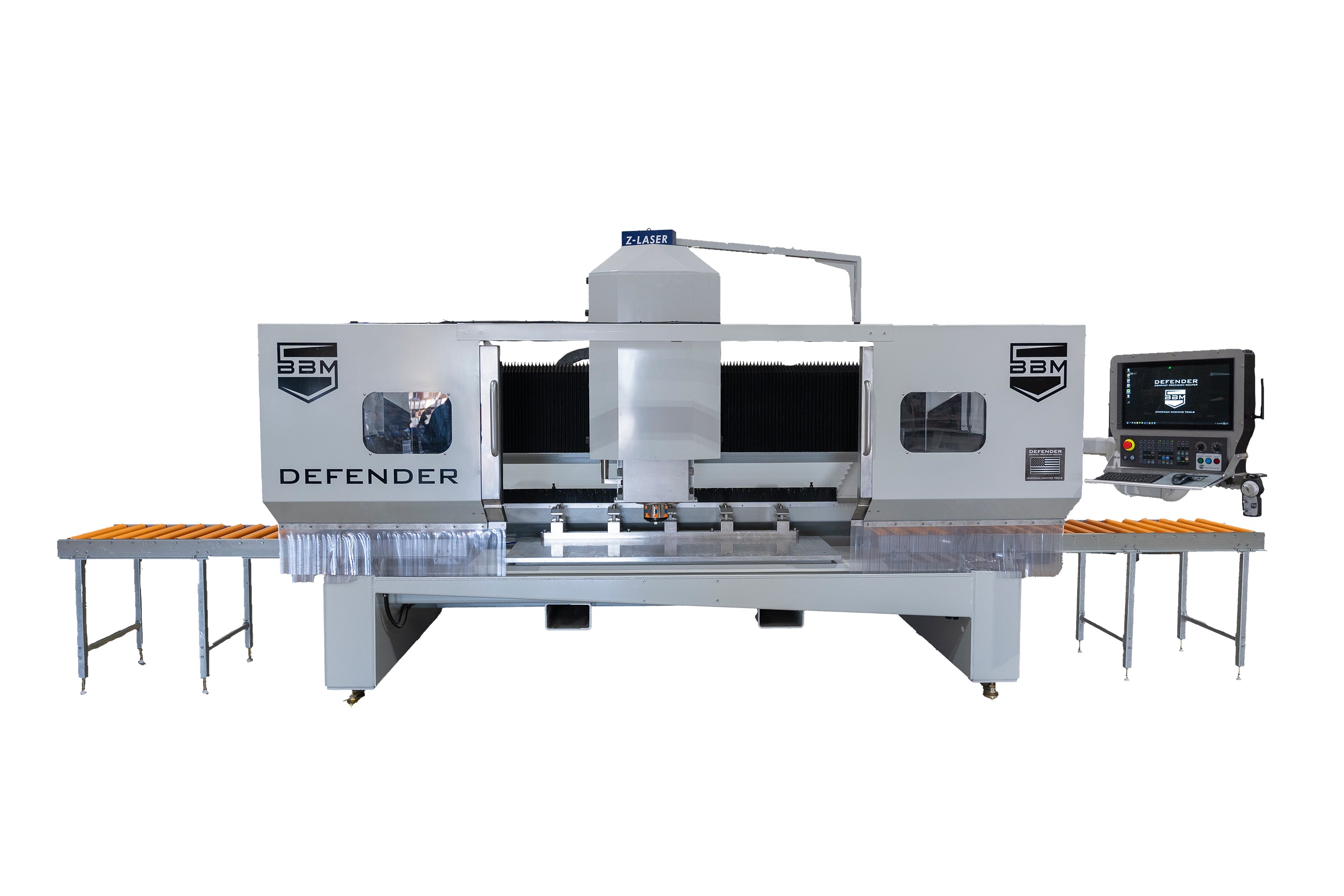

DEFENDER CNC STONE ROUTER

The World’s First Compact Precision CNC Stone Router

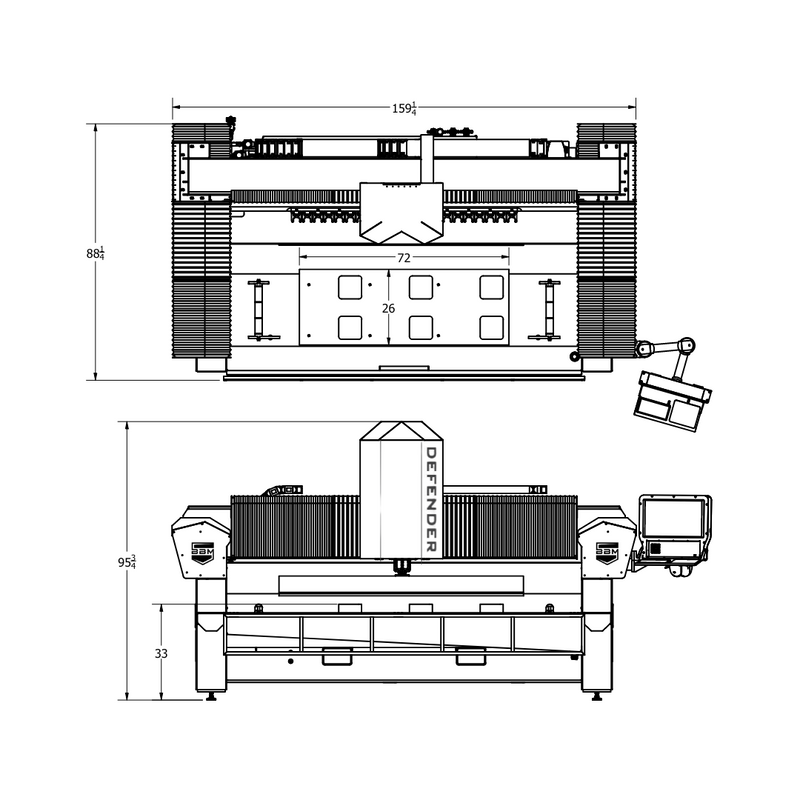

The DEFENDER CNC stone router is a groundbreaking addition to your shop's automation, revolutionizing the way you work with stone. Compact, yet powerful, this machine boasts an impressive footprint of 159” by 88”, making it an ideal fit for any shop, regardless of size.

WHERE ADVANCED TECHNOLOGY MEETS COMPACT DESIGN

The DEFENDER isn’t just a machine– it's a comprehensive solution that elevates your production to new heights at an affordable price. Its combination of compact design, advanced technology and versatile capabilities make it an indispensable tool for anyone working with stone. When it comes to the DEFENDER, you’re not just investing in a machine– you're investing in the future of your business.

COMPACT

72” Processing Box

DURABLE

Direct Drive System

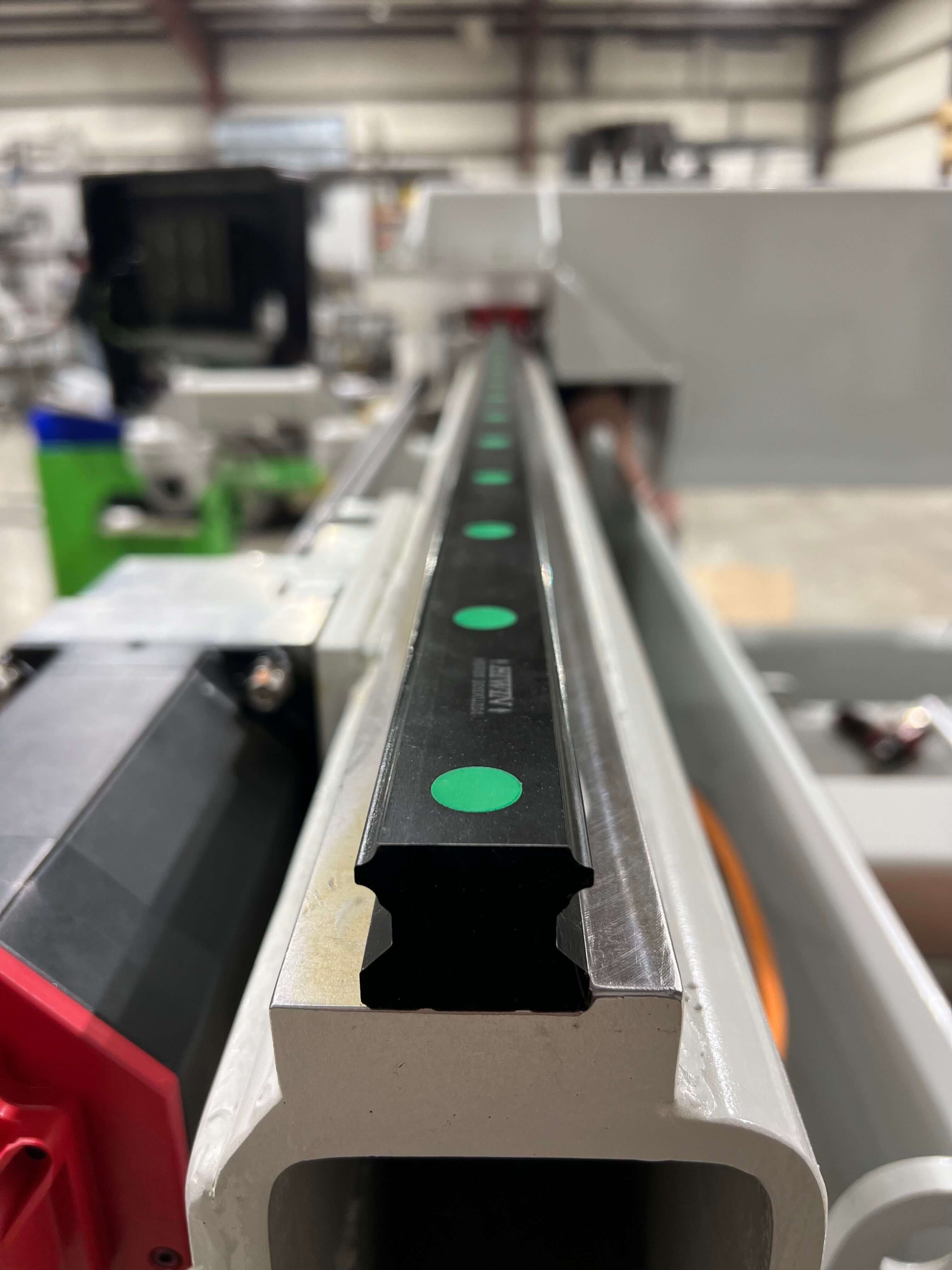

PRECISE

Precision Linear Rails

THE DEFENDER GENERAL MACHINE SPECIFICATIONS

Rigid monoblock superstructure

Solid welded frame and bridge make moving and installation hassle-free

Program with AlphaCam

Programing is easy with stone industry-leading AlphaCam software

Direct Drive system

Every axis, including the spindle, is directly driven with servo motors. Less parts equals less downtime

In Feed and out Feed Tables

Streamline workflow by enabling a continous three-stage operation: staging materials, active processing, and recieving finished. This setup minimizes downtime, optimizes material handling and boosts overall productivity for high-volume or custom projects.

Automatic Doors

Enhanced safety and efficiency with automatic doors. When the cycle starts, the doors close automatically to contain water and debris, ensuring a cleaner and safer work environment. Once the cycle finishes, the doors open automaticallly, allowing for seamless material handling and reducing operator intervention for improved productivity.

Easy Countertop Clamp System

The intuitive clamping system securely holds countertops in place with minimal effort. Aligning the sink’s centerline with the center clamp arrow ensures quick, precise positioning every time. This feature reduces setup times, improving efficiency and consistency in production.

Precision Ball Screws

The high-precision ball screw drive is aerospace quality, providing the most accurate drive system on the market

72”x 30” Processing Box

Large processing table allows you to completely finish your part, inside and out

21.5” Inch Touch Screen

You won't miss a thing programming on this 21.5" wide screen display.

DEFENDER Locate System

Quick-locating stop system allows you to bump your part to a fixed position, hard stop and go!

Optional Overhead Z- Laser

Part and pod alignment laser make this machine easy to operate for anyone. Reduce mistakes and visually verify parts before you finish them.

BBM Commander Software

Industy-leading COMMANDER machine operating software reduces operator steps and seamlessly integrates into any programming software

21 ISO 40 Tool Holders & Cones

21 position automatic tool change allows for two loaded hull sets of profile tools, as well as room for all accessory tools to complete any job.

12 Month Warranty

We stand by our machine with a full bumper-to-bumper warranty for 12 months from date of installation

Proven industrial design

BBM is setting new standards for stone fabrication technology. Our machines are simply designed better.

WHY CHOOSE A DEFENDER?

Versatility

Small floor plan design allows placement in any shop.

Cut and polish sinks on ANY size slab or remnant

With a large 21 position tool changer, you have endless opportunities to load the machine to finish your part completely.

Load and unload with a Manzelli style lifter or use optional in-feed out-feed tables

Enjoy unloading directly with a manzelli-style vacuum lifter or use optional in and out feed tables.

Dress normal seams or mill euro miter ones

Mill drainboards and Waterfalls

Use the power of AlphaCam to design any project for this machine.

Build and mill farm sinks

Use the power of AlphaCam to design any project for this machine.

If the vanity is six feet long or less, profile and polish the edges, and more.

Simply load the part on vacuum pods and finish the entire part.