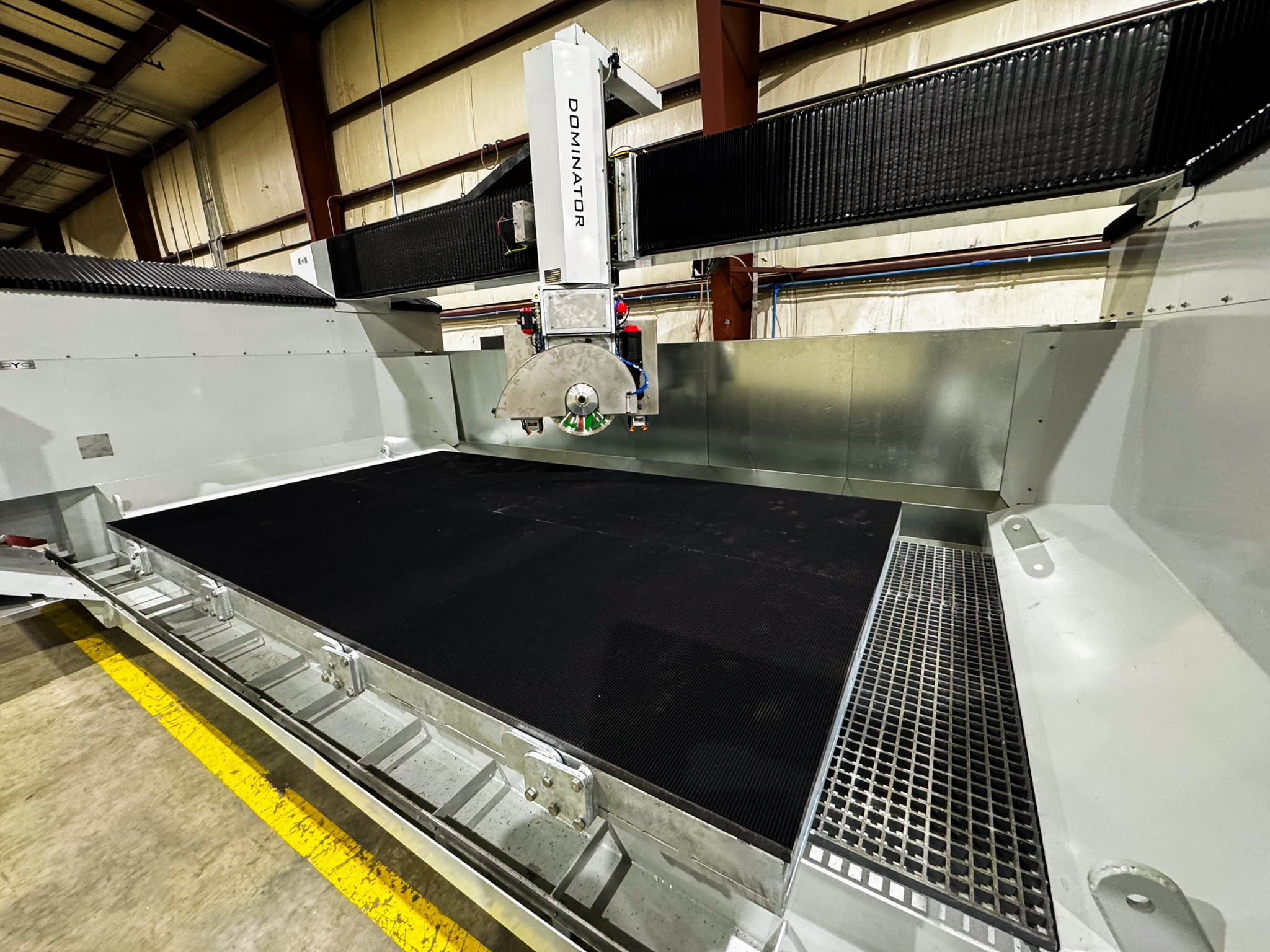

The Dominator

The First American-Made 5 Axis Saw with Dual Sided Spindle

The Dominator 5-Axis CNC Saw is proudly built in America at BBM’s Shelbyville, KY headquarters. We prioritize quality and reliability, ensuring that every machine meets the highest standards. We carefully source and assemble our saws to deliver superior performance and long-term durability.

Listening to Those Who Matter Most — Our Customers

Great machine design doesn’t happen by accident—it’s the result of practical experience, precision engineering, and a deep understanding of fabricators' needs. Whether it’s hardware, software, or workflow efficiency, every innovation in The DOMINATOR comes from listening to our customers. At BBM, that’s what we do every day.

Building a Better Machine

Through our experience rebuilding machines, we gained deep insight into common failure points. That knowledge has shaped the Dominator’s design, eliminating weaknesses and engineering solutions to increase reliability and performance. When you look closely, you’ll see the difference.

Why Choose the Dominator

Mono-Block Steel Construction

The DOMINATOR’s foundation is engineered for unmatched durability, weighing in at 19,000 pounds of American steel, expertly welded into a single, seamless structure at our Shelbyville, KY factory. This mono-block steel construction minimizes vibration for precision cuts, simplifies installation and relocation, and ensures long-term rigidity even under the toughest conditions. Built like a tank.

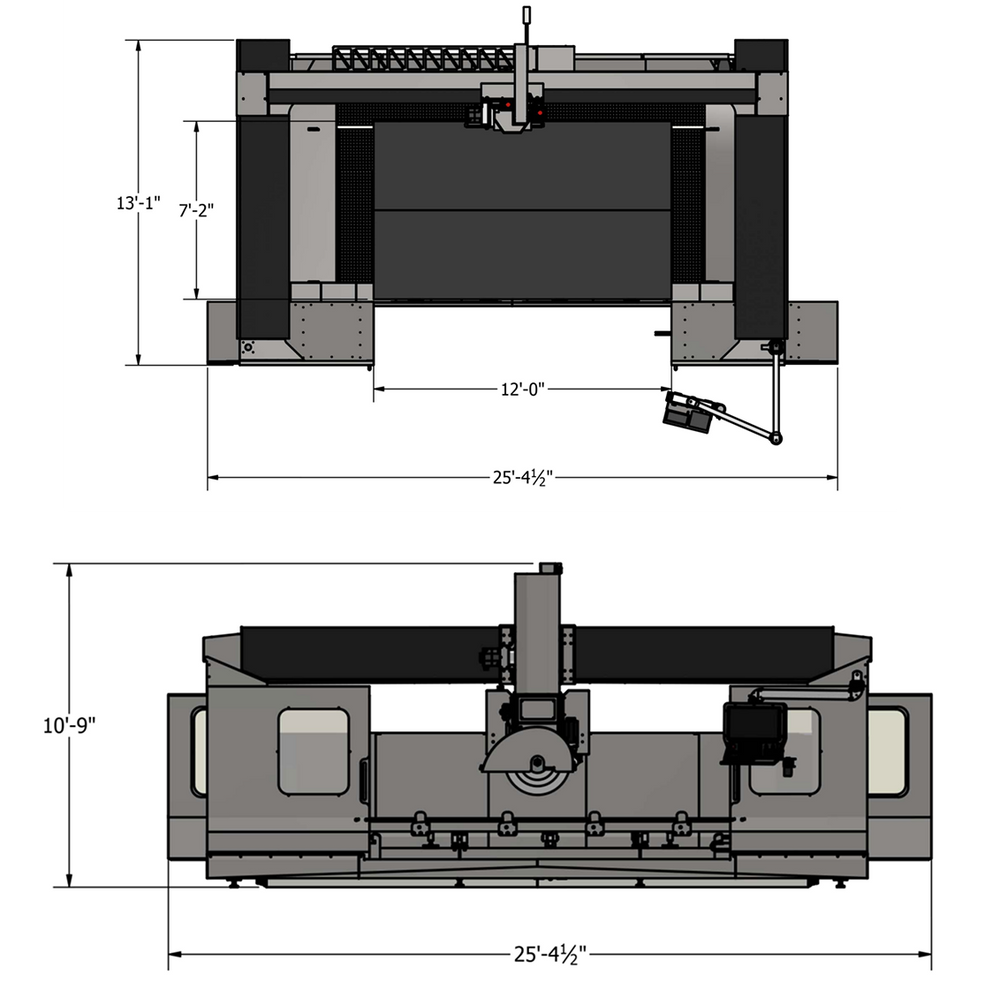

144” x 86” Full-Coverage Cutting Table with Mitering Anywhere

The Dominator’s expansive 144” x 86” cutting table accommodates large slabs with ease, streamlining production for even the most demanding projects. With the ability to perform straight or miter cuts anywhere on the table, there’s no need to reposition slabs for full-length miters. This saves time, reduces handling risks, and ensures precision across the entire slab.

Galvanized Tilting Table with Advanced Cutting Mat

Offers seamless slab handling by enabling operators to load full granite slabs with ease, eliminating the need for a vacuum lift. The cutting mat is engineered for superior vibration dampening, ensuring stable cuts and extending tool life. Its deflective properties reduce wear, providing long-lasting durability and enhancing overall precision during cutting operations.

Fanuc Motion Controls

When it comes to motion control, the DOMINATOR is equipped with state-of-the-art Japanese FANUC servo controllers and drives, ensuring unmatched precision, reliability, and efficiency. Featuring separate knobs for feed speed and RPM control, operators can make on-the-fly adjustments with ease, achieving precise cutting control for any material or application. BBM’s commitment to quality ensures every movement is smooth and accurate, delivering consistent, high-performance results for even the most demanding tasks.

Precision Ball Screws

The true advantage of precision ball screws becomes increasingly evident as the machine ages.

Unlike other systems, ball screws excel at maintaining exceptional accuracy and virtually eliminate gear backlash over time, ensuring consistent performance even after years of use. Simply put, it’s a superior design that sets the Dominator apart and keeps your operation running at peak precision.

Much Bigger Bearings

When it comes to bearings, size matter and at 35mm on the X, Y, and Z axes, the Dominator stands above the competition. These larger linear bearings ensure ultra-smooth traversing, reduced toroidal and axial play, and unmatched longevity. Dive into the details, and it becomes clear: not all machines are created equal.

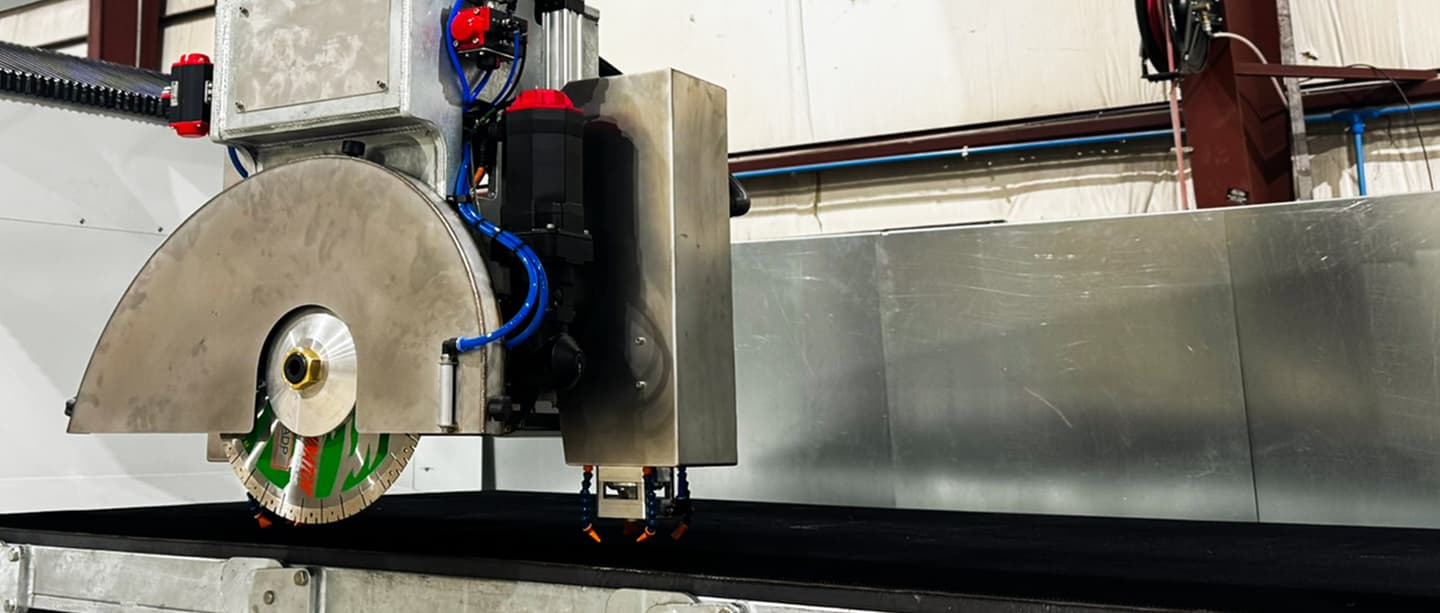

35 HP Saccardo Saw Motor (1000rpm-4500rpm)

The DOMINATOR features a 35 HP Saccardo low-profile electrospindle with advanced air cooling, delivering smooth, precise cuts on materials ranging from soft to ultra-hard stone. Engineered for efficiency, it combines adjustable speeds with high torque to handle demanding operations while extending blade life and maximizing productivity.

14” – 26” Blade Size Range

The flexible blade size range allows for versatile cutting capabilities, from precise detail work with a 14-inch blade to tackling large-scale projects with a 26-inch blade. This adaptability ensures the machine can efficiently handle a wide variety of material sizes and thicknesses, making it an ideal solution for diverse project requirements.

Servo Miter Technology (0-49 Degrees)

This advanced technology ensures precise mitering for seamless angled cuts, even on the hardest materials. Its automated adjustments save time and effort, delivering smooth transitions and perfect seams across mitered edges. Designed for versatility, it enhances fabrication capabilities for complex projects with consistent accuracy.

Laser Alignment System

The DOMINATOR is equipped with a precision laser alignment system, allowing operators to quickly and accurately visualize cut lines for manual cutting when necessary. This feature enhances flexibility, ensuring seamless adjustments and efficient part positioning, minimizing material waste and setup time.

12,000 RPM Fanuc Drive Side Spindle

This high-speed spindle is engineered for precise incremental cutting, quickly handling intricate details like inside corners on granite, quartz, porcelain, and ultra-compact materials. Paired with the saw, it ensures smooth transitions and flawless finishes on complex cuts. The HydroSculptTM through-tool cooling system prevents overheating and extends tool life, making it ideal for demanding applications and premium results.

3500 RPM Fanuc Secondary Side Spindle

Optimized for heavy-duty core drilling, this spindle delivers precision and efficiency, even on the thickest and hardest stones. Its low vibration design ensures deep, straight holes while minimizing material stress. With advanced cooling capabilities, it reduces heat buildup, extends tool life, and maintains the integrity of premium materials.

Material Thickness Probe

This feature automatically measures and adjusts for variable material thickness, ensuring precise and accurate cuts every time. By optimizing miter size and depth, it reduces errors, minimizes rework, and improves material yield. Ideal for mixed material batches and irregular natural stones, it simplifies setup and enhances overall production efficiency.

Blade and Tool Measurement System

This system automates calibration to ensure precise cuts and extended tool life. It measures the blade's radius as it wears and adjusts the length of tools in both Side Spindle 1 and Side Spindle 2. By maintaining accurate settings, it enhances cutting performance, reduces downtime, and improves overall efficiency.

Alphacam and BBM EasyCutTM Programming System

The DOMINATOR features Alphacam, the industry leader in CAD/CAM software, and the intuitive BBM EasyCut Programming System. Together, they streamline job setup, enhance operator efficiency, and ensure precise, efficient programming for all your CNC needs.

Overhead Photo Position System

Simplifies job setup with an overhead camera that captures a detailed image of the slab. Operators can drag and drop parts onto the image, and the DOMINATOR cuts precisely as displayed. This streamlines alignment, speeds up processing of slabs and remnants, and ensures efficient, accurate production.

21¹⁄₂ Inch FANUC Touchscreen and Intuitive Workstation

The DOMINATOR features a 21¹⁄₂ inch-wide FANUC touchscreen integrated with a thoughtfully designed control unit for superior ergonomics and usability. The BBM HMI (Human-Machine Interface), developed by BBM engineers, provides a modern, intuitive layout that displays vital information clearly and efficiently. This combination ensures an enhanced operator experience, making machine operation seamless and productive.

Complete Water Containment

The Dominator 5-Axis CNC Saw is designed with a complete water containment system to manage water flow efficiently. This system keeps the workspace cleaner, reduces slip hazards, and directs used water for proper drainage, preventing uncontrolled runoff. It also helps protect sensitive components from excess moisture, ensuring long-term reliability.

Simplified Tech Maintenance

All CNC machines require routine maintenance. At BBM, we’ve designed Commander software to make these routine maintenance steps easy. This software automates reminders of when tasks are due. One click of a button will show you a queue of upcoming maintenance duties.

Made in America

The Dominator 5-Axis CNC Saw is proudly built in America at BBM’s Shelbyville, KY headquarters. We prioritize quality and reliability, ensuring that every machine meets the highest standards. We carefully source and assemble our saws to deliver superior performance and long-term durability.

Z-Axis Crash Detection

Every Dominator 5-Axis CNC Saw comes standard with Z-Axis Crash Detection, an advanced safeguard designed to protect your machine. This system continuously monitors pressure on the saw head throughout the cutting process, preventing potential damage from excessive force or operator errors. Without this essential feature, the risk of costly repairs and downtime increases.

Automated Lubrication System

Delivers consistent oil to critical components, reducing wear and ensuring long-term performance. In the demanding environment of a stone shop, this system protects your investment by minimizing friction and maintenance needs. Less upkeep, more cutting—because we know you have better things to do.

Automatic Doors

Designed for efficiency and cleanliness, automatic doors close at the start of the cutting cycle to keep debris contained within the enclosure. Once the cycle is complete, they open automatically, allowing for quick cleanup and easy reloading. This feature enhances safety, reduces dust exposure, and streamlines workflow.

Two-Year Warranty

BBM stands behind the Dominator 5-Axis CNC Saw with a two-year parts warranty and a one-year labor warranty, ensuring your investment is protected. With expert support and service, we’re committed to keeping your machine running at peak performance. Quality you can trust, service you can count on—that’s the BBM way.